Radiation Effects Facility

Radiation Effects Facility

The Cyclotron Institute's Radiation Effects Facility now offers a second dedicated beam line for proton and heavy ion testing.

Combining an H-minus ion source with the re-commissioned K150 cyclotron, we offer protons with tunable energies from 6.3 to 45 MeV. Additional energies can be provided as low as 2 MeV with our degrader system. Maximum flux for these beams is on the order of 1x109 particles/cm2/s.

The K150 beam line is also available for heavy ion testing with sets of 9.4 MeV/u and 15 MeV/u beams.

As with our K500 heavy ion testing beam line, we provide diagnostic equipment for complete dosimetry analysis and beam quality assurance. Test control and monitoring are conducted with the same custom SEUSS software that is used for K500 heavy ion testing. Dosimetry at low flux (1x107 particles/cm2/s and lower) is conducted using an array of five detectors comprised of plastic scintillators coupled to photomultiplier tubes. For higher fluxes, uniformity is first adjusted at a lower flux and then a set of four tantalum foils are used to back-scatter protons into four additional detectors. After a calibration measurement, dosimetry relies on these back-scattering measurements.

There are three available beam exposure diameters: 1.0", 1.5", and 1.75" for both heavy ions and protons. For heavy ions 0.001" thick aramica film is used for the 1.0" diameter vacuum window. A 0.0015" thick aramica film is used for the 1.5" and 1.75" diameters. For protons the 1.0" exit window is 0.002" thick aluminum. The 1.5" and 1.75" diameter exit windows use a 0.003" thick aluminum window.

We offer a range of heavy ions with our K150 beam line with two sets of energies per nucleon to choose from: 9.4 MeV/u & 15 MeV/u. The 9.4 MeV/u beams provide LETs from 0.1 MeV/(mg/cm2) up to 28.1 MeV/(mg/cm2). Ions included in this set are: He, N, Ne, Ar, V, Cu, Kr, Ag, and Xe. The 15 MeV/u beams provide LETs from 0.1 to 28.2 MeV/(mg/cm2). Ions in the 15 MeV/u set are: He, N, Ne, Ar, V, Cu, and Kr. Click here for the K150 Heavy Ion beam list.

Protons can be extracted from the K150 cyclotron at any energy between 6.3 to 45 MeV. Tuning times between energies are typically between 30-60 minutes.

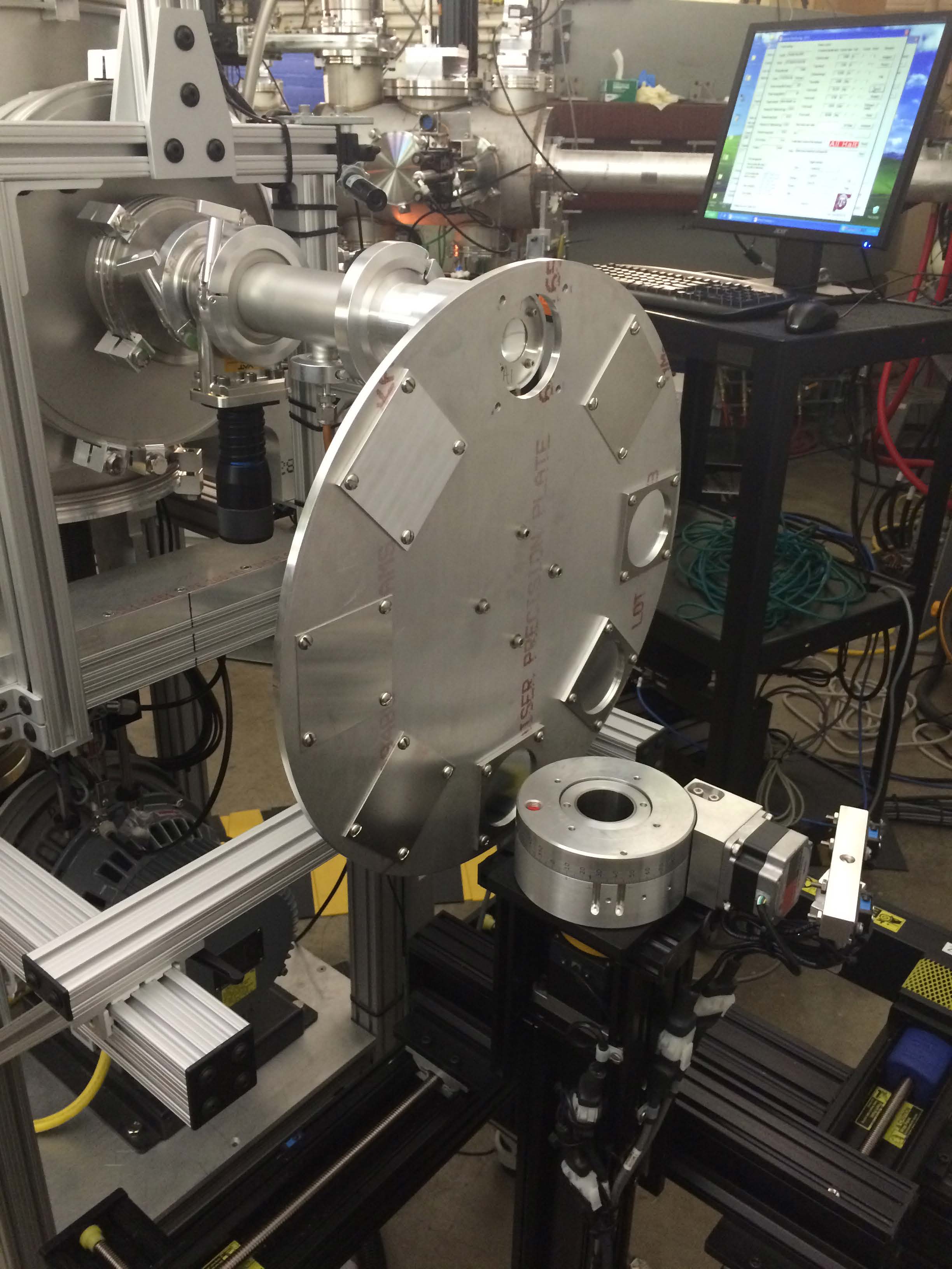

A degrader system consisting of aluminum plates on a rotatable wheel is available and can be used to change beam energy without cyclotron re-tuning. Letting us know in advance what energies will be needed, the degraders on the wheel can be customized for your test. Placement in front of the beam is remotely computer controlled.

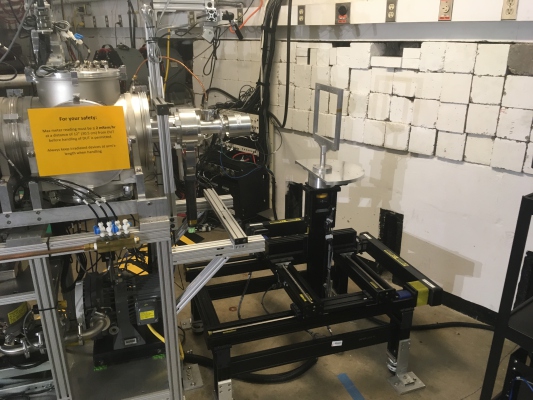

An in-air station is located at the end of our proton beam line. This station consist of a rotating platform and a removable target mounting fixture identical to that used in our heavy ion beam line. Frame and platter dimensions are also identical.

TARGET MOUNTING

The mounting fixture for the in-air station has the same dimensions as that of the heavy ion fixture. Specifications for a typical board to be mounted are detailed here . The mounting fixture is removable and is attached to a rotary platter. Detailed drawing of the frame is also available. The platter is 15 1/4" in diameter and can hold a load up to 40 lbs. For mounting directly to the platter please refer to this drawing.

TARGET POSITIONING SYSTEM

The in-air station allows for the motion of the target in four directions: X, Y, Z and Theta. X and Y are the horizontal and the vertical axis in the target plane, respectively. The Z-axis is in the direction of the beam-line, with theta being the clockwise and counter-clockwise rotation about the y-axis.

Hot Air Blower

A hot air blower is available for our guest to use to heat devices under test. The blower can be controlled locally at the unit or remotely from the data room. For operational instructions you can view the remote use manuals here:

Remote Operation

Quick Start Guide

The K150 data room is located directly above the hallway outside of the testing vault. The room is cooled and well insulated from building noise. Included inside the room are four video monitors for test observation and three 27" hdmi compatible monitors for user laptops. Wired internet connections are available inside the data room and in the K150 setup area just outside. Temporary wireless network accounts are also available.

CABLING

Patch panels connect the data room to the testing area. The panels include two DSUB-9 serial connections, two DSUB-25 serial connections, four usb 2.0 connections, ten BNC signal cable connections (RG-58), four BNC video cable (RG-59) connections, and five RJ45 jacks (CAT6 cable) .

Custom cables can also be run to the testing area. Distances from the test stand to various locations:

1 )57 feet to the table in the hallway.

2) 69 feetto a table top just above the conduit hole outside the data room .

3) 80 feet to just inside the data room.

4) 100 feet to the far end of the data room.

The K150 setup area is located just outside the data room. This area can be used for test prep and equipment storage during your visit. We have various tools and supplies stored in nearby cabinets and tool boxes. Work tables in the setup area offer access to wired network connections. Wireless access is also available upon request. For your convenience we provide a full-sized refrigerator, microwave oven and coffee maker.